List of pages

Please select one of the pages from the list below.

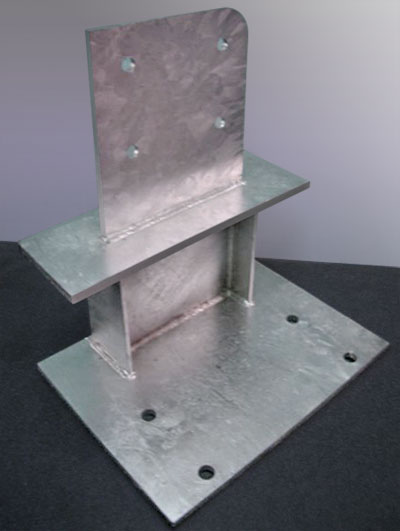

Galvanising

The Hot-Dip Galvanising process

Materials are immersed in molten zinc at a temperature of 450ºC until they reach the same high temperature as the zinc. The products are then gradually withdrawn to allow excess zinc to drain off (hence all fabrications must have sufficient drainage holes). The coated products are then quenched or air-cooled depending on client requirements.

The appearance of finished galvanised coatings can differ according to the chemical composition of the steel substrate being used.

The final effect can range from bright and shiny to a dull grey colour, the dullness caused by steel containing higher silicon levels.

However, the high level of protection afforded by galvanising coatings remains the same, regardless of their outward colour. The process will safeguard mild steel against corrosion in an external UK environment for between 40 to 70 years, and for over 100 years in indoor locations. However, there may be micro-climatic conditions that reduce this life expectancy, although these are the exception to the rule.

General Galvanised Coating thickness:

Material Thickness Average CoatingLess than 1.5mm 45 microns

1.5mm – 3mm 55 microns

3mm – 6mm 70 microns

6mm+ 85 microns